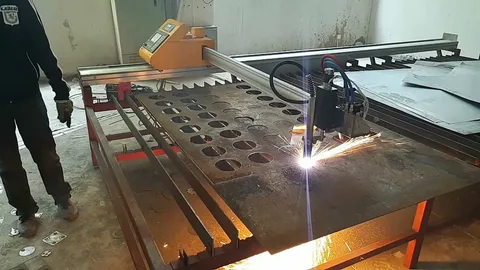

Stepping up to a plasma cutter for the first time can feel energizing—bright arcs, moving gantries, and the precision of automated cutting all working together. But behind every smooth cut is focused training that teaches operators how to control heat, movement, software, and safety at the same time. Learning to run a CNC plasma cutting machine is a hands-on journey that blends technical skill with practical shop awareness.

Learning Basic Machine Safety and Protective Gear Use

Safety begins with understanding how the machine behaves under power. A CNC plasma cutter produces extreme heat, bright light, and hot debris, so operators must use gear designed to protect eyes, skin, and hearing. Training covers shield requirements, flame-resistant clothing, and grounding procedures that prevent arc flash or electrical shock. Safety also includes workspace habits. Operators learn how to manage cords, avoid loose material on the table, and maintain safe distance from the torch during cutting. A strong foundation in safety builds confidence and reduces accidents, setting a stable base for the more technical skills to follow.

Understanding CNC Software and Program Input Methods

Software knowledge is central to plasma cutting. Operators must understand how to import drawings, apply toolpaths, and adjust settings to match material thickness. CNC companies near me often provide software tutorials for their machines, helping users become comfortable with control panels and interface navigation.

Program input methods vary by machine. Some systems accept direct code entry, while others rely on drag-and-drop design tools. Learning how to preview cuts, adjust offsets, and verify paths ensures the CNC plasma cutting machine follows the exact pattern needed without wasted material.

Training on Proper Torch Setup and Height Calibration

Torch setup affects the quality of every cut. Operators learn how to align the torch, inspect consumables, and position the nozzle for clean pierces. This training teaches them to recognize wear patterns and replace parts before they affect performance.

Height calibration is another key step. The distance between the torch and the metal controls arc stability, edge smoothness, and dross formation. A CNC plasma cutter typically includes an automated height control system, but operators must still understand the principles behind it to correct issues quickly.

How to Position and Secure Metal Stock Before Cutting

Material preparation influences cut accuracy. Training shows operators how to place metal squarely on the cutting surface, eliminate gaps, and secure thin sheets that may vibrate under the arc. Proper positioning ensures the cut follows the programmed line without distortion.

Operators also learn how to account for metal bowing or warping. Adjustments may include adding supports, re-leveling the slats, or repositioning the stock for best contact. A CNC machine company often instructs users on handling various material sizes, from small sheets to full plate.

Instruction on Gas Choice and Pressure Settings

Different gases serve different purposes in plasma cutting. Operators learn whether to use clean air, nitrogen, or gas blends depending on the metal type and thickness. Proper gas selection affects efficiency, edge quality, and consumable lifespan.

Pressure settings also matter. Too much pressure can blow molten metal unevenly, while too little produces weak arcs. Training teaches operators how to verify flow rates and listen for signs of irregular gas output—skills that improve consistency over time.

Reading Blueprints and Translating Shapes to CNC Code

Blueprint literacy turns design into motion. Operators learn how to interpret line types, tolerances, part orientation, and kerf expectations. These details determine how the plasma cutter must move across the material.

Translating shapes into CNC code involves understanding toolpaths, lead-ins, and pierce points. This training ensures the plasma cutting system accounts for cut width and maintains accuracy. Once mastered, operators can convert complex drawings into precise cuts efficiently.

Hands-on Practice Adjusting Pierce and Cut Speeds

Speed control is one of the most important elements of training. Pierce speed determines how quickly the arc penetrates the material without damaging the torch or creating excessive spatter. Cut speed controls how smooth and clean the final edge appears.

Hands-on practice teaches operators how to balance speed with voltage, amperage, and material behavior. This experience is essential because different metals react differently under the arc. Learning to make adjustments in real time prepares operators for the variety of jobs a CNC plasma cutter handles.

Maintenance Routines for Consumables and Drive Systems

Maintenance keeps a plasma cutter performing predictably. Operators learn how to inspect electrodes, nozzles, swirl rings, and coolant systems. Replacing consumables at the right time prevents inconsistent cuts and reduces downtime. Drive systems also require care. Training includes lubrication practices, tension checks, table cleaning, and gantry inspection. These habits extend machine life and protect motion accuracy. Understanding maintenance procedures is key to getting long-term value from any CNC plasma cutting machine.

Operating a CNC plasma system requires structured training, practice, and ongoing support. Amtec Solutions Group helps teams gain confidence through tailored instruction, reliable equipment, and integrated automation solutions that make learning efficient and production-ready.